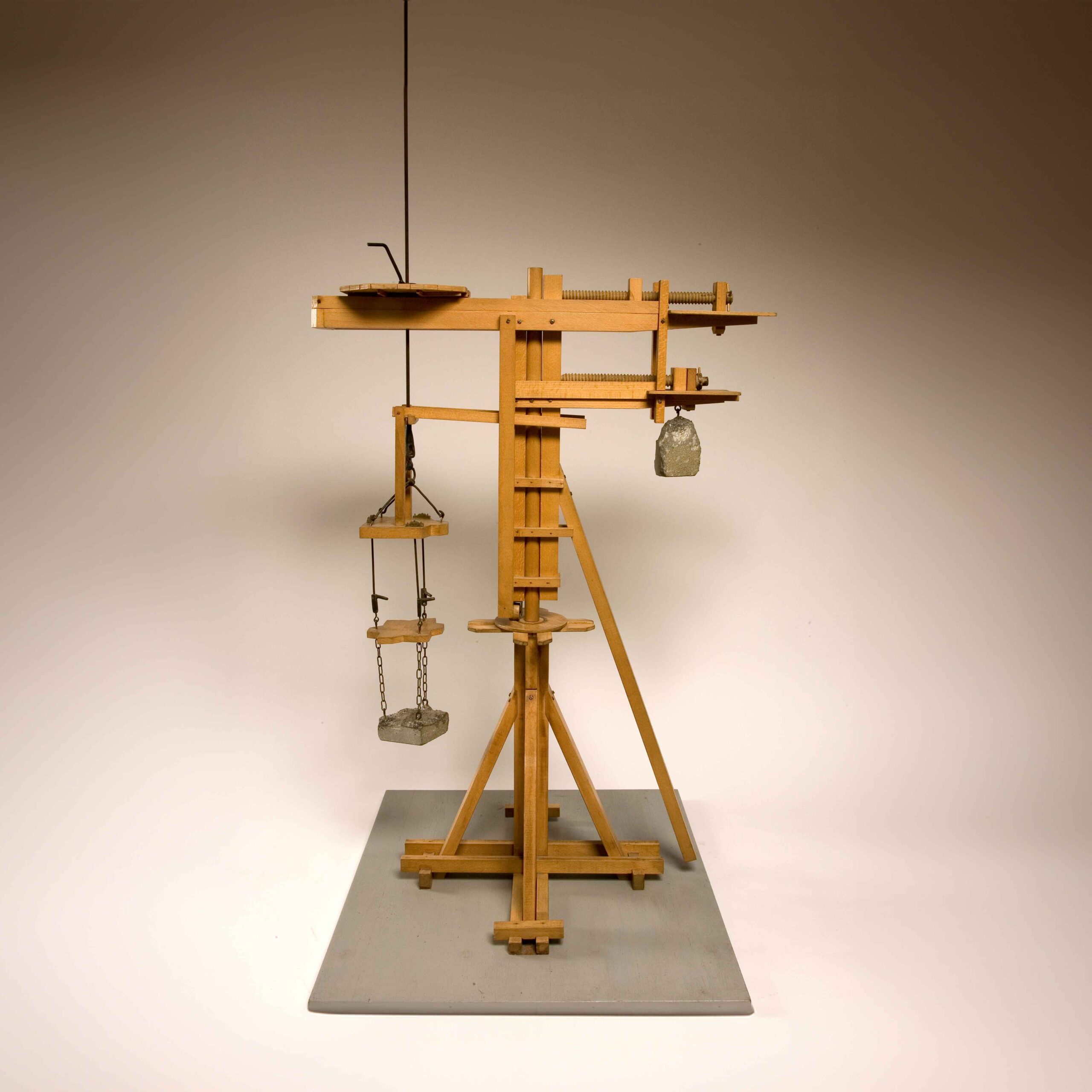

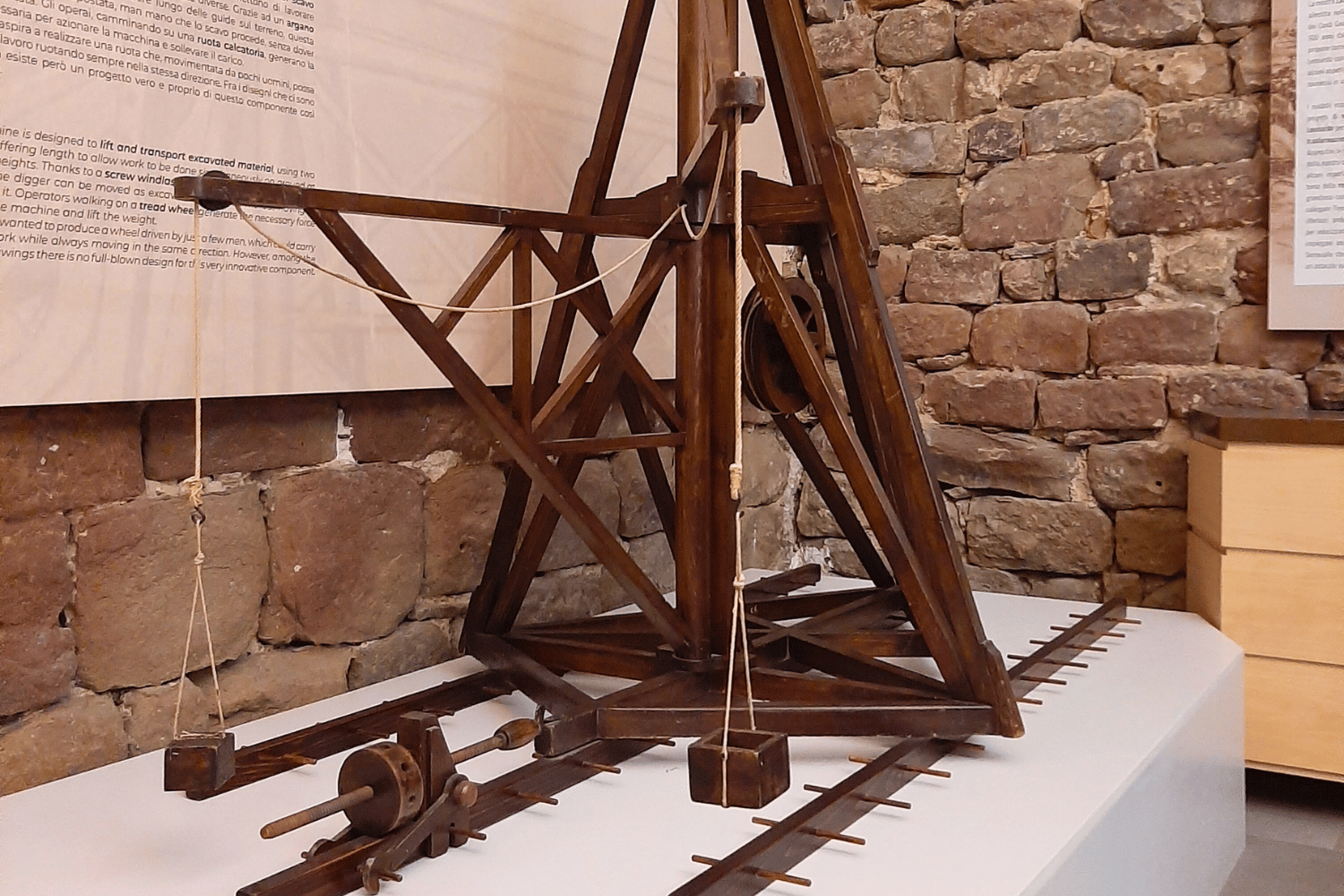

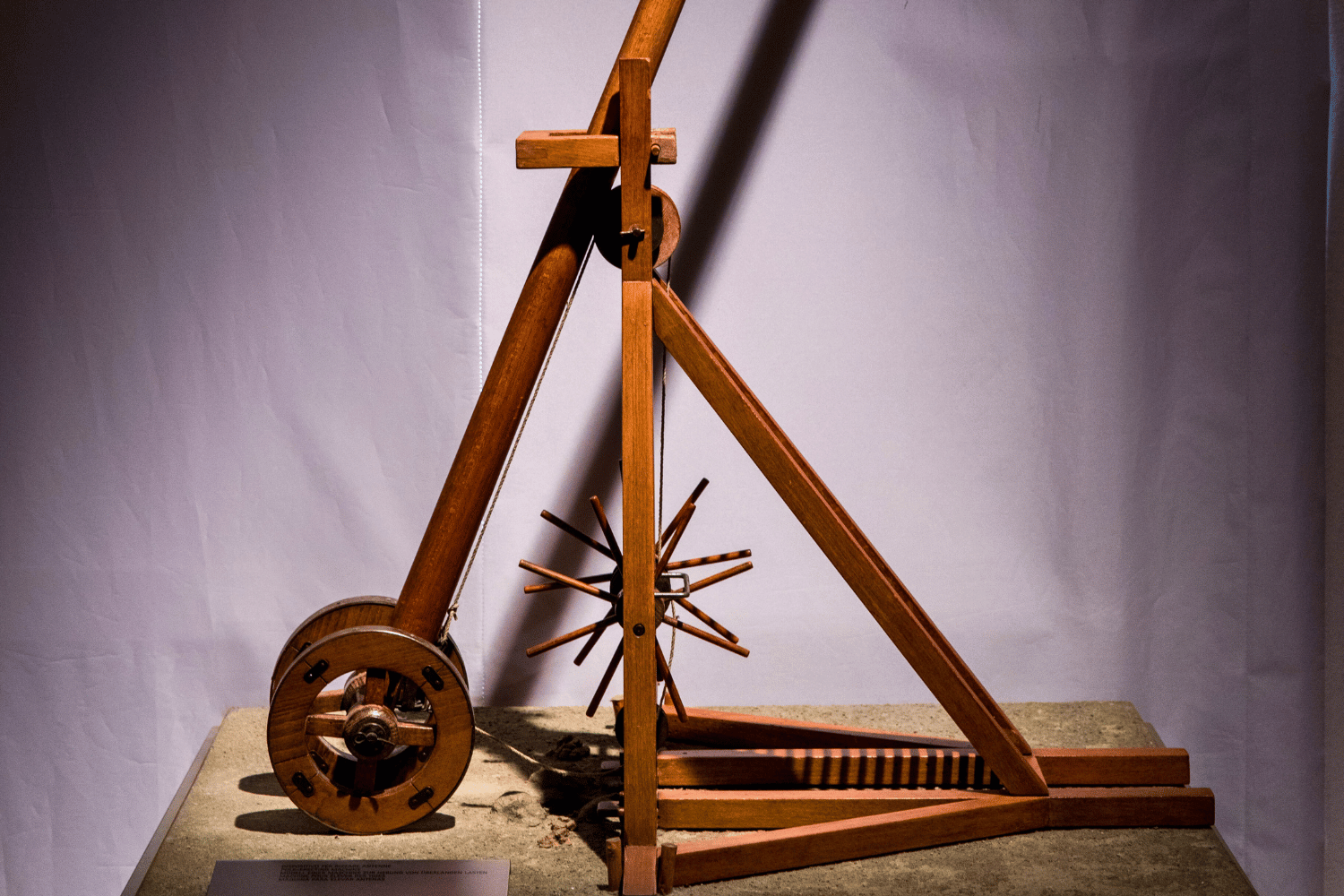

This machine was used to lift and transport excavation material using two or more arms of different lengths, which allowed work on multiple levels simultaneously.

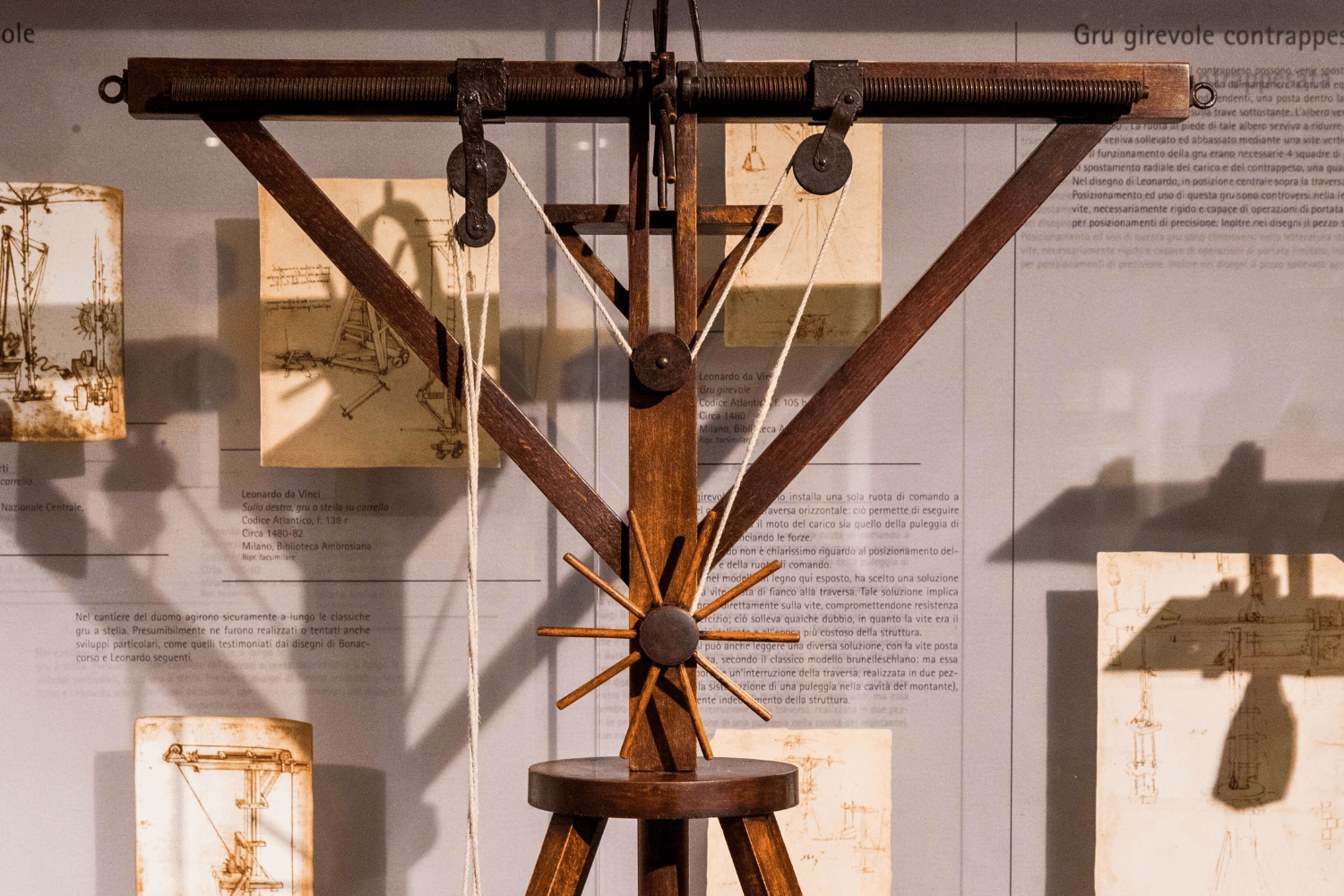

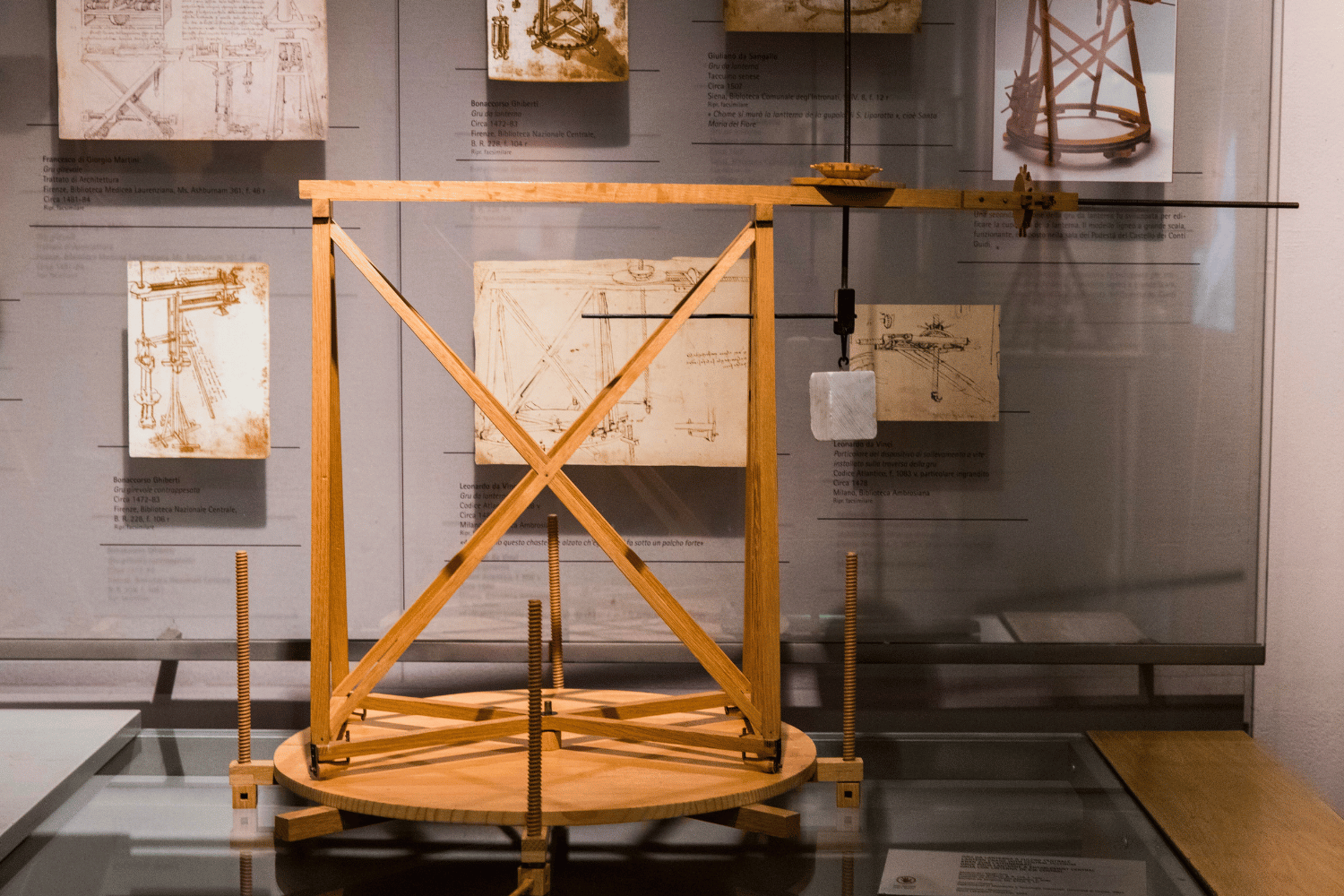

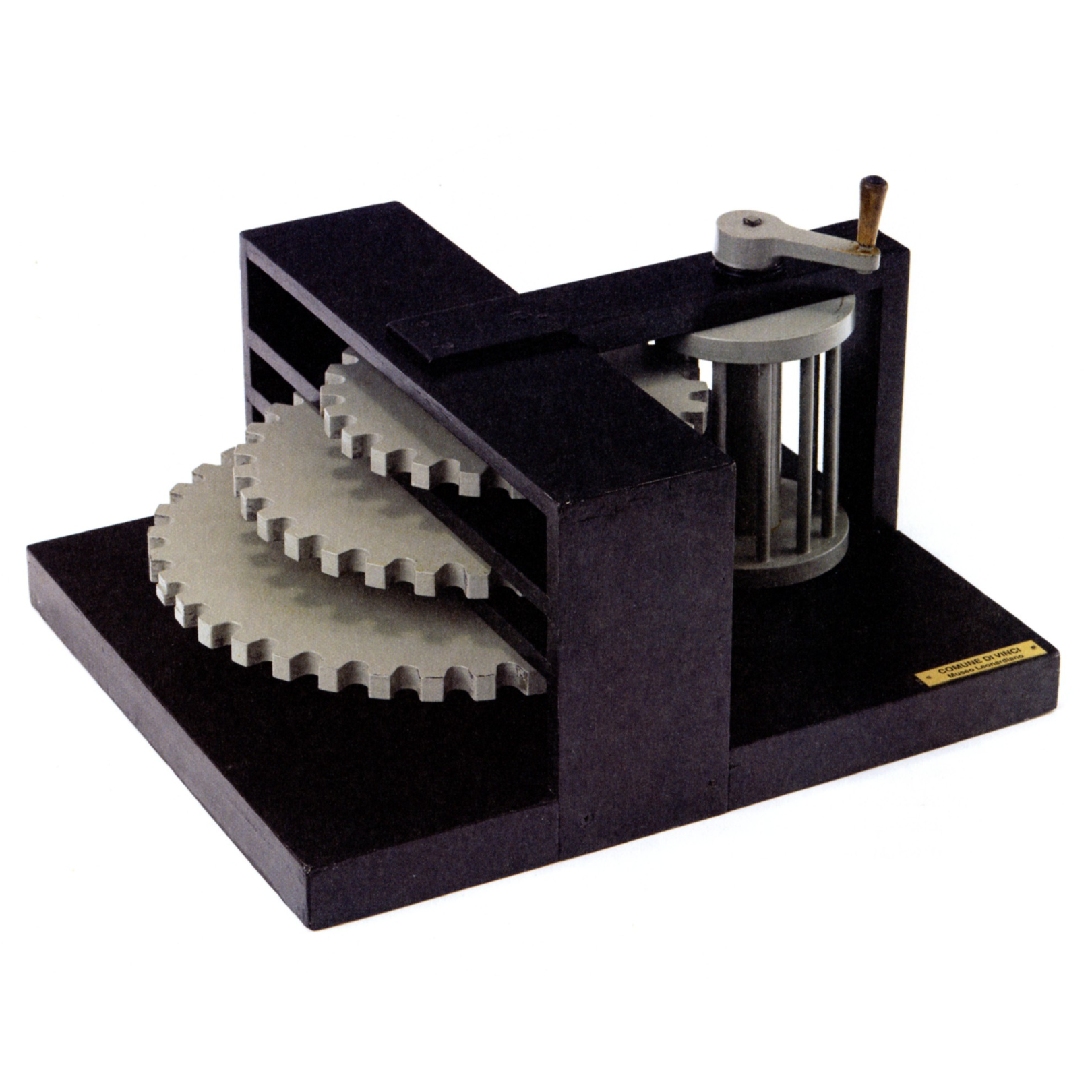

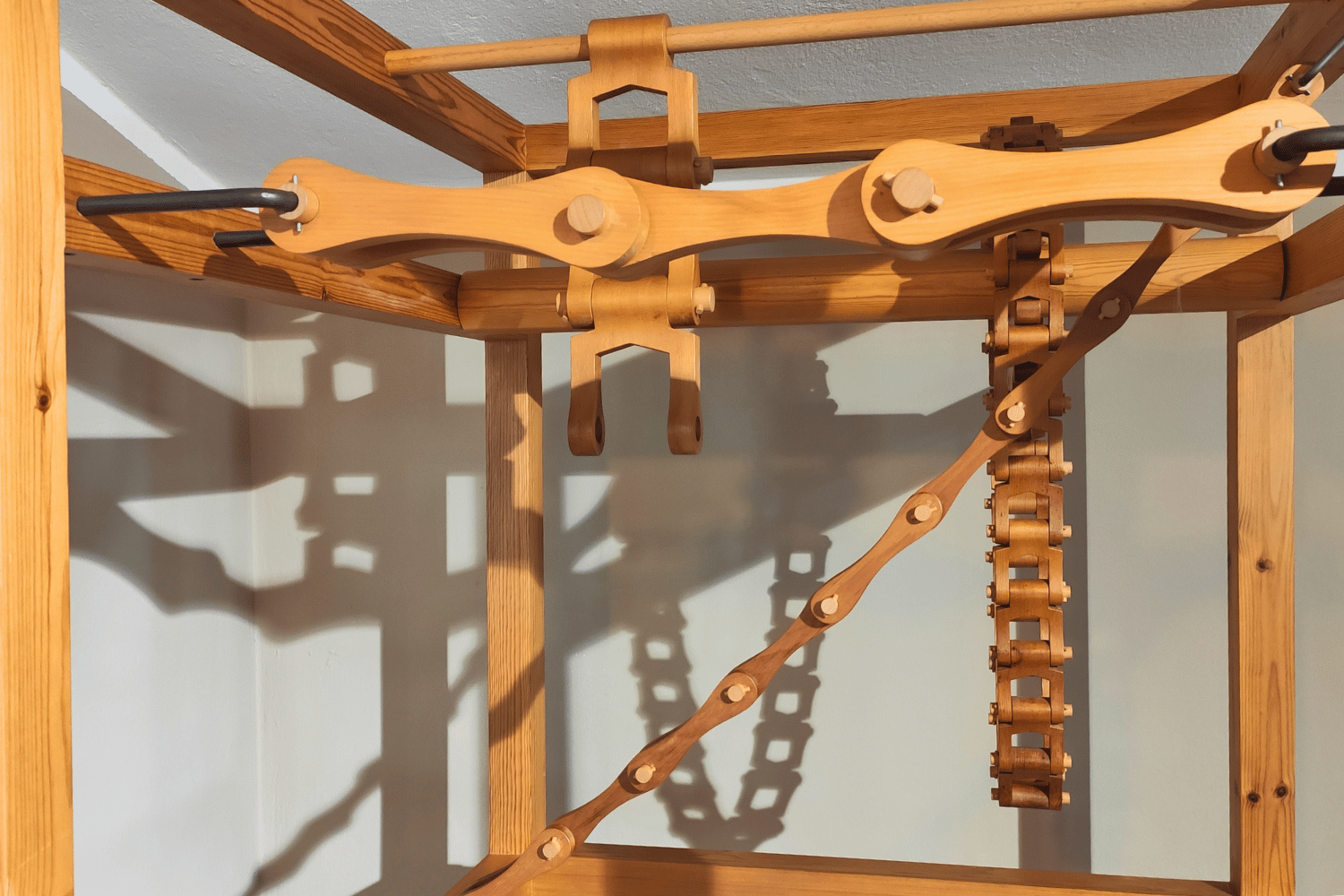

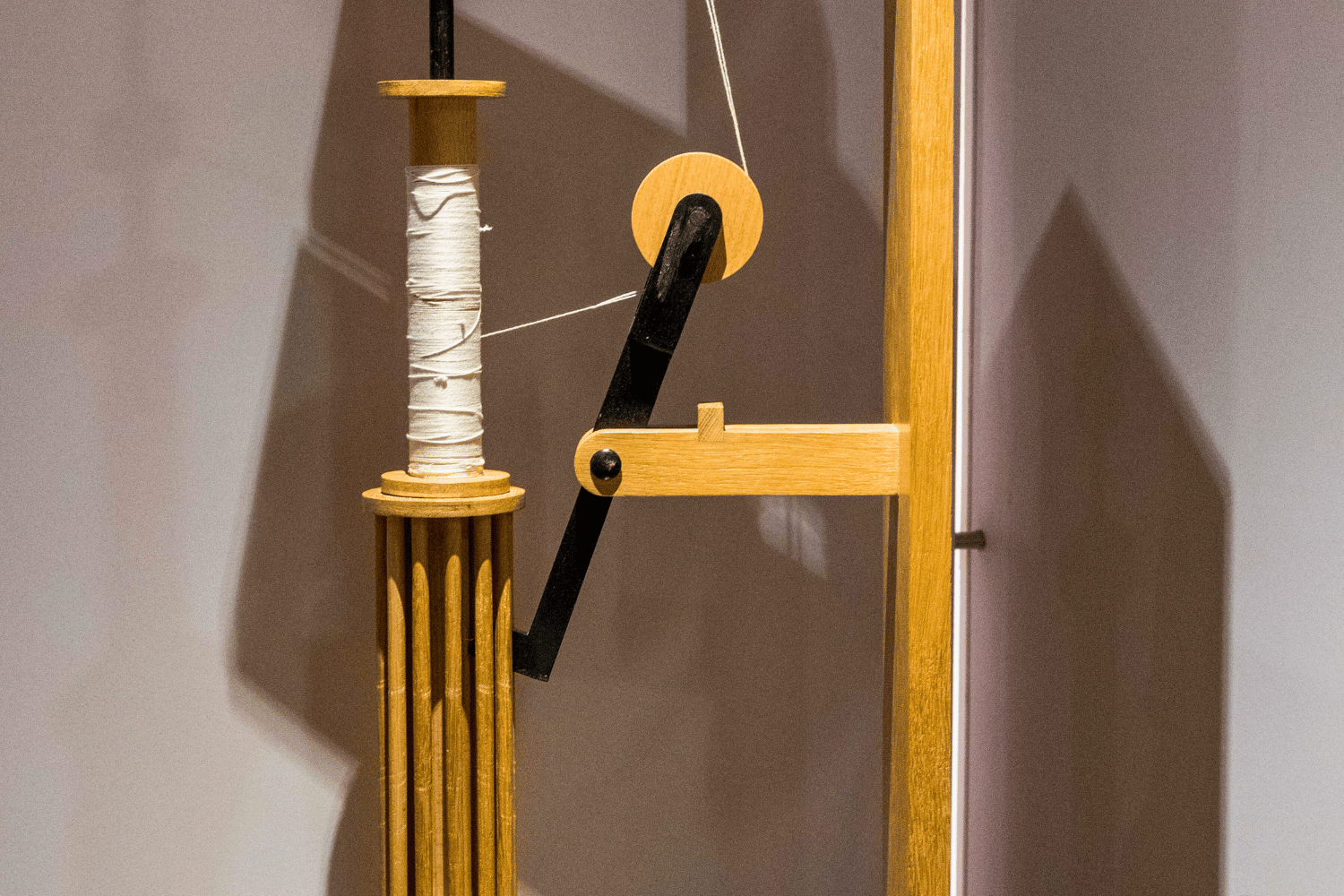

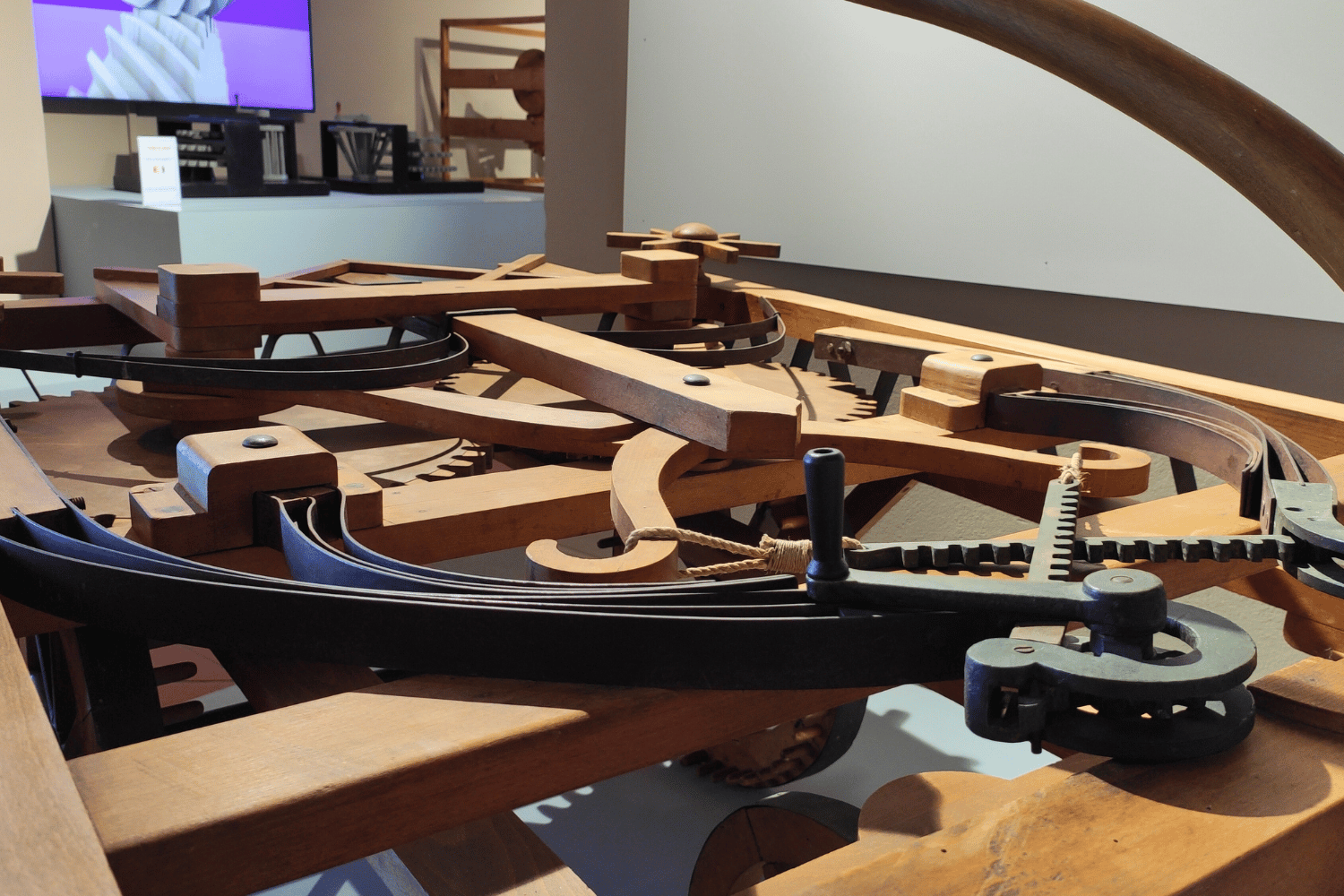

The model features a vertical axis around which the horizontally positioned arms rotate; at the ends of these arms are pulleys that enable the raising and lowering of containers used to transport the excavation material. The movement of the containers is controlled through ropes passing over a central control pulley. The containers are shaped like rectangular boxes, and their bottoms are divided lengthwise into two free segments held along the central axis by metal hinges or leather strips; they are also equipped with legs for resting on the ground, positioned to extend beyond the width of the bottom segments.

The outer ends of these segments are connected by cords passing through specific holes to a hook that suspends the container. The cords, kept taut by the weight of the container itself, keep the two bottom segments closed, holding in the material placed inside. When the containers descend and rest on their legs on the ground, the tension in the cords is released, and the weight of the material causes the two bottom segments to automatically open downward, emptying the containers. When the containers are lifted again, the bottom automatically closes.

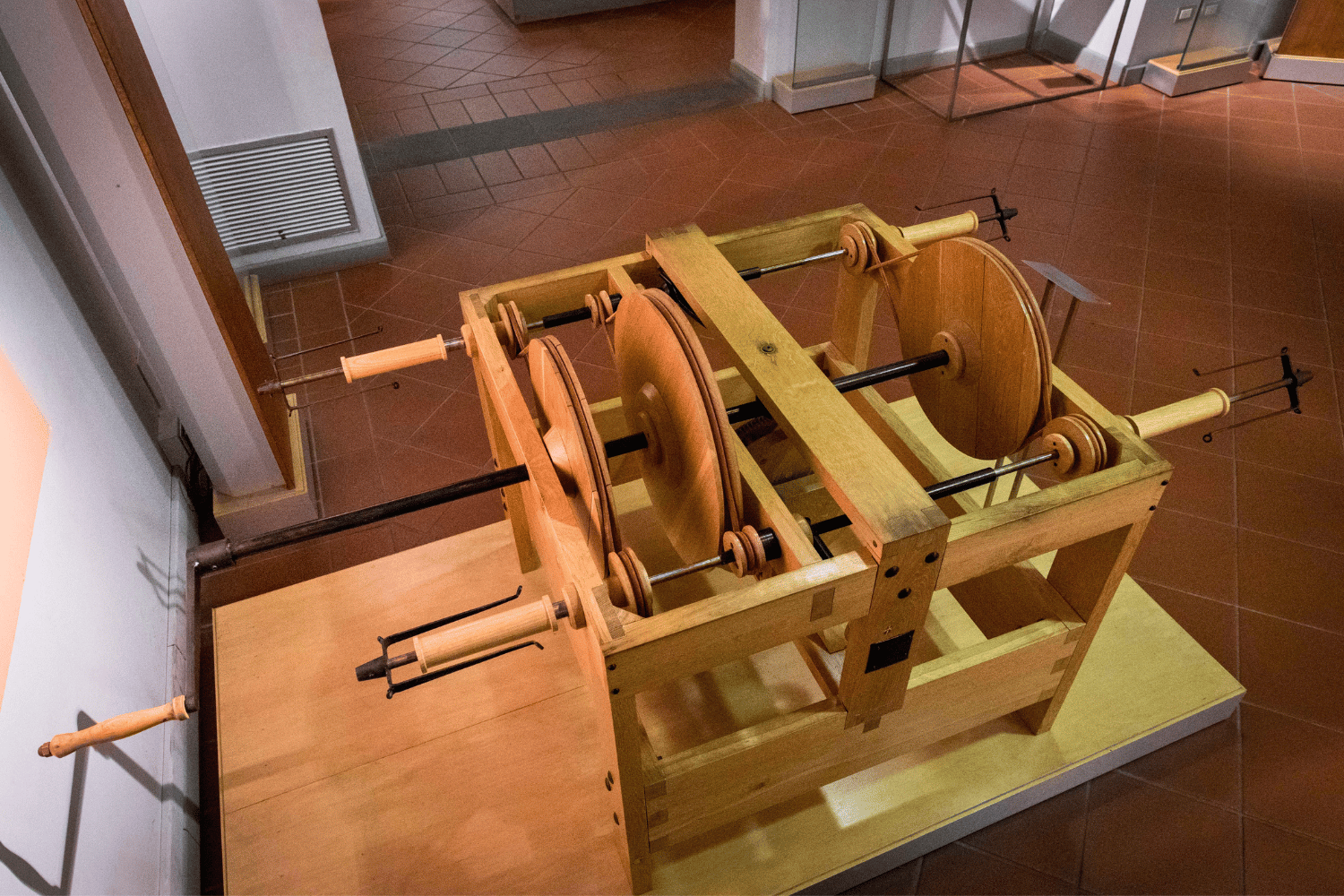

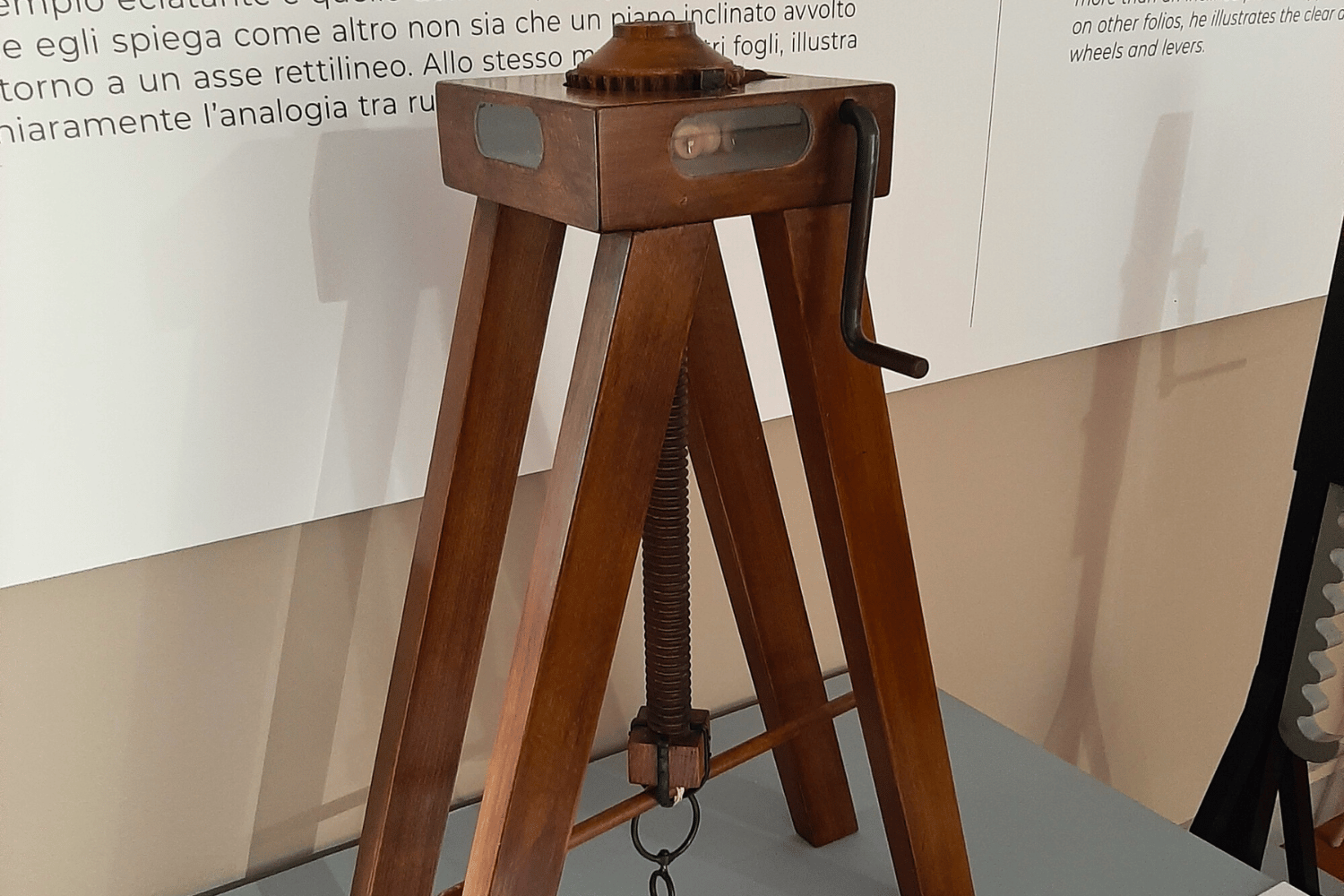

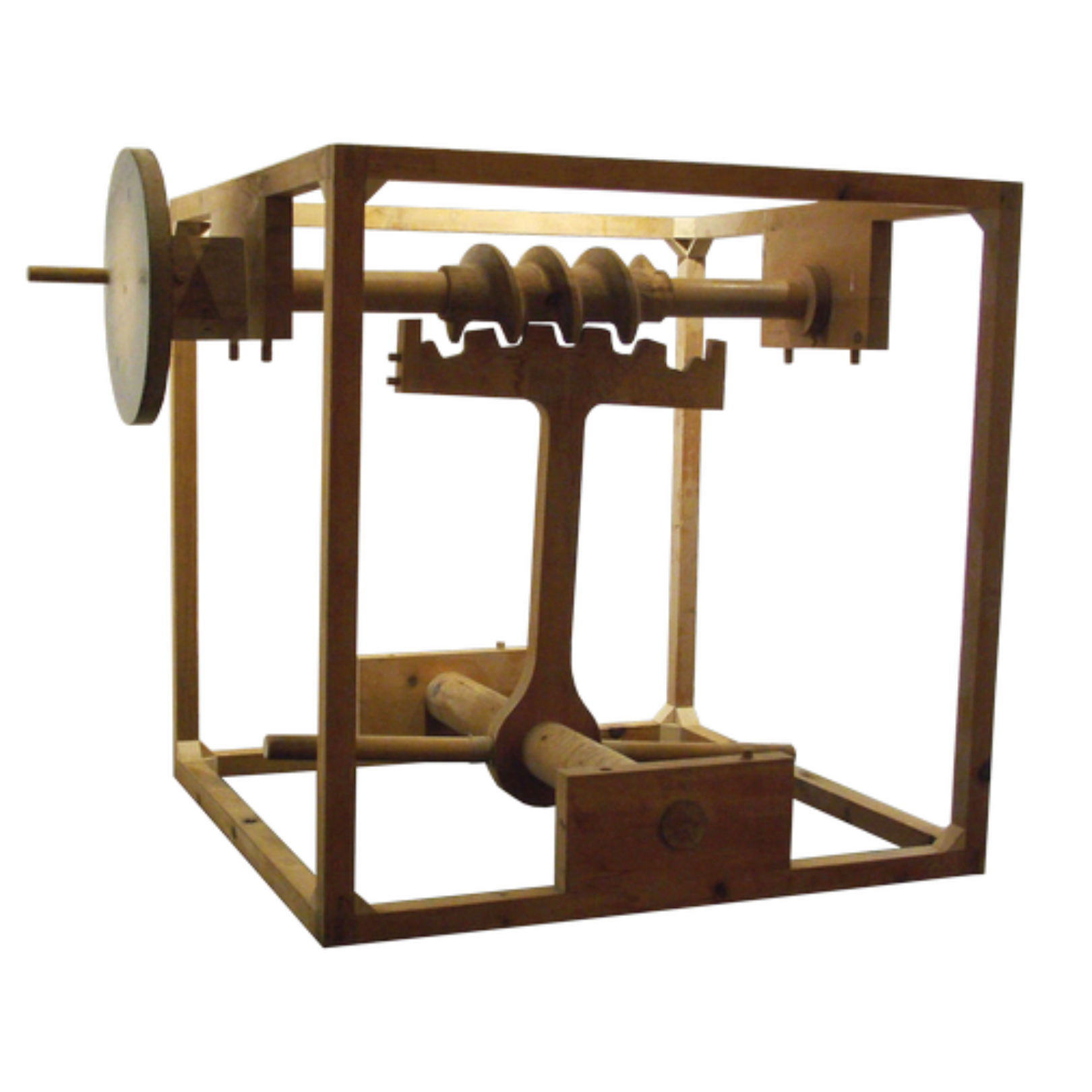

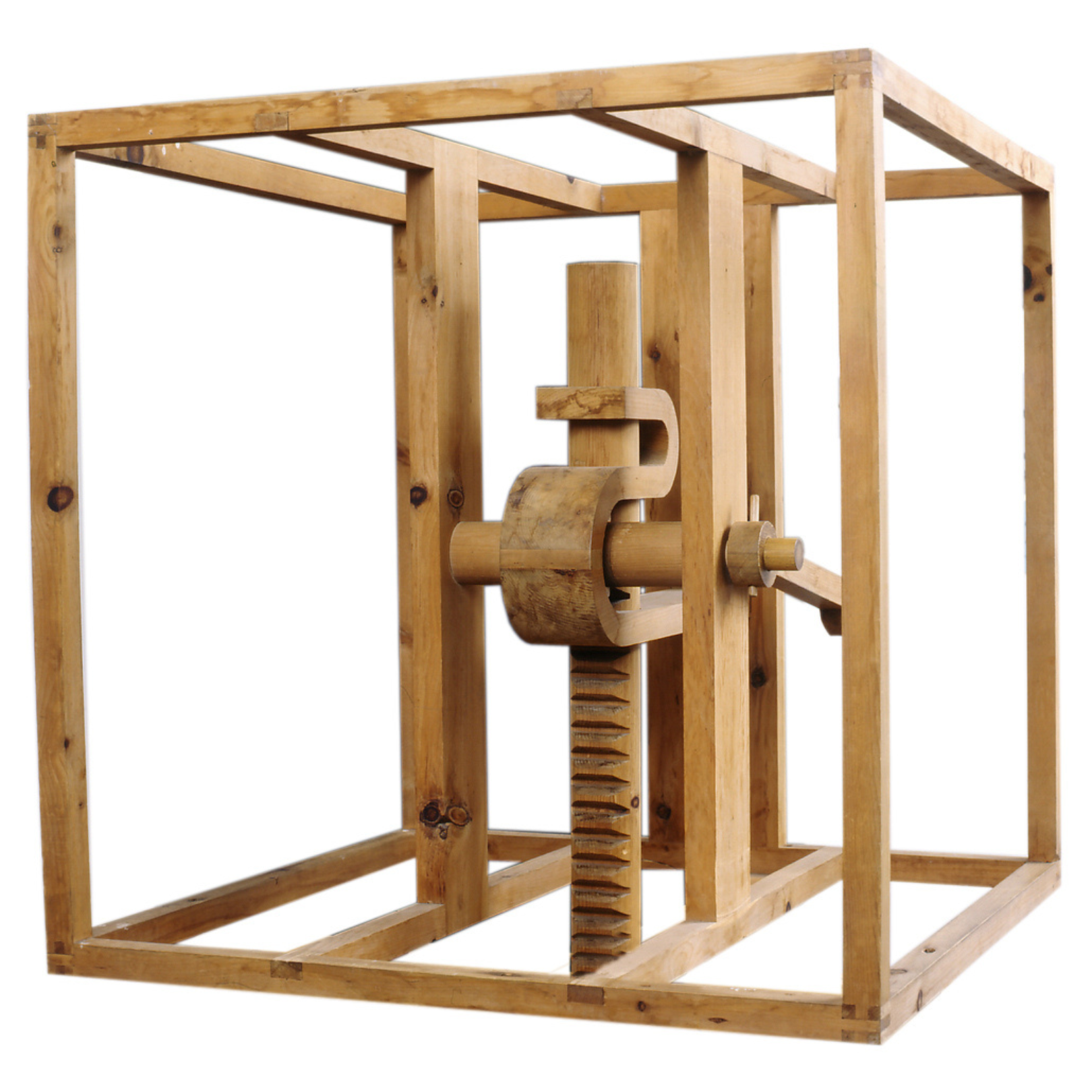

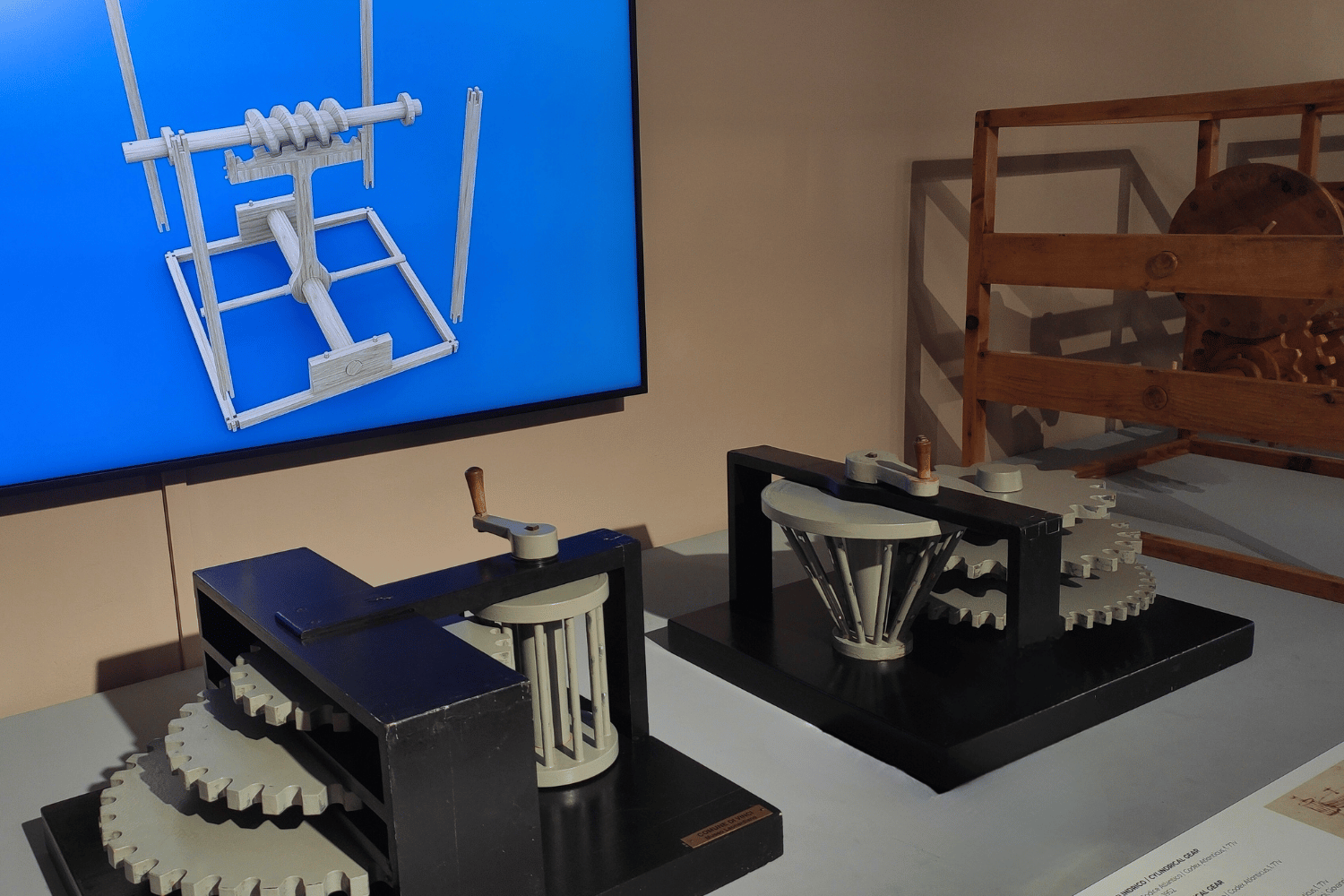

The machine, pulled by a rope connected at a distance to a horizontal winch with a screw and worm gear, could move forward over the ground by sliding along special “guides”; in this way, it did not need to be dismantled as the excavation progressed.